Line Isolation & Hydrostatic Weld Testing

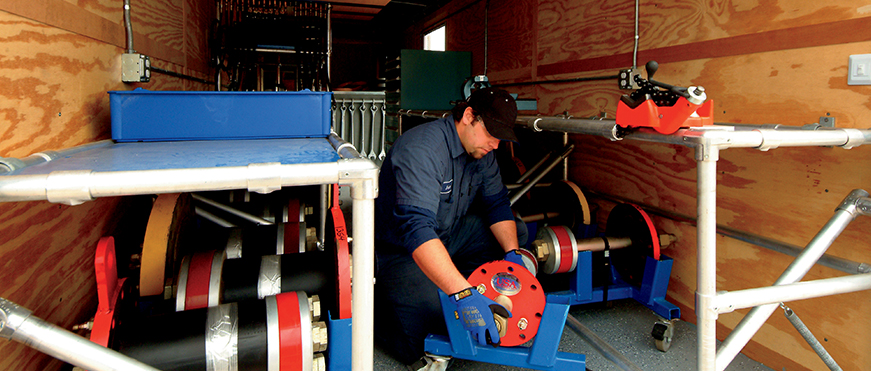

TEAM's line isolation tools promote the welder’s safety by isolating any upstream gases or vapor while welding repairs are affected to the pipe. During this process the annular cavity is monitored via the tool’s built-in through-port venting system that allows for any pressures to be evacuated to a safe environment. TEAM's tools can be back pressure rated up to the burst pressure of the pipe and have a minimum standard rating of 25 psi back pressure.Once welding has completed, the same tool used for the isolation can then be pull forward to center the annular testing cavity on the new weld which provides a mechanism to perform a localized hydrostatic weld test on the new weld. Tool sizes can accommodate pipes ranging from 0.5″ to 120″ and test pressures up to 5,000 psi.

In addition to our internal isolation and weld testing tools, TEAM also provides external hydrostatic nozzle testing; no longer does a vessel need to be completely filled with water water to perform a traditional hydro-test on nozzle additions. TEAM's nozzle testers allow for additions to be tested externally in a safe and cost-efficient manner with a minimal amount of water. This approach can save time and money from a shutdown schedule by allowing other craft to work simultaneously inside of the vessel while testing is completed.

Custom engineered solutions to accommodate most any Isolation/Weld testing requirements are also avaiable upon request.

TEAM can help your company:

- Utilize equipment with a smaller footprint and for easy installation and removal

- Provide the ability to isolate in conditions where the pipe is pitted, corroded, eroded and out of round

- Monitor the annular area of the tool in order to verify isolation

- Through-port any up-stream gas, vapor or pressures away to a safe environment, as well as purge through the center

- Test additiona in a safe and cost-effective manner